|

|

|

| NEWS |

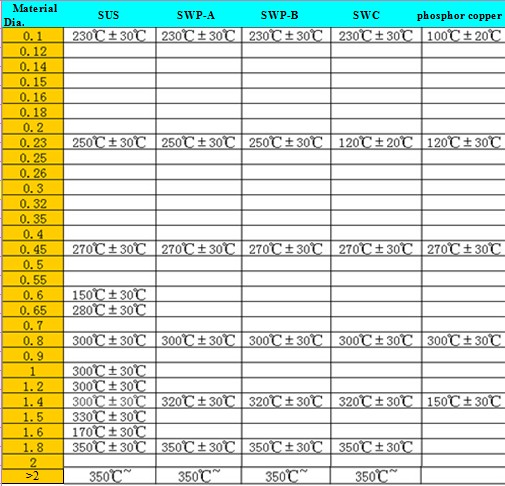

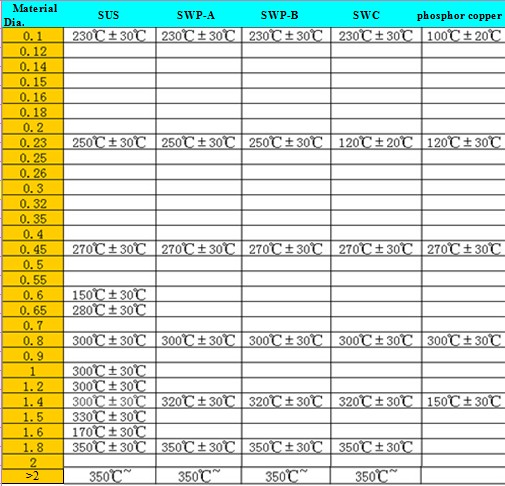

| the standard heat-treatment specification of the spiral spring

|

| |

The heat-treated of spiral spring is that put the spiral spring within the certain medium to heat, keep warm and get cooling. It is a kind of metal heat working process by changing the material surface internal metal organization structure to control the performance. It is a frequently used process of power spring at present. Generally, heat treated do not change the shape of steel and chemical composition, but change its internal structure to achieve its work to maximize performance, extend the service life of the product, and save material and energy.

The heat treatment of power spring is not easy to handle, but has a standard. Dongguan Yongsheng Metal Products Co., Ltd, has specialized in product developing and producing of power spring, spiral spring , and coil spring for 15 year. The following is to introduce the standard for heat treatment.

Description:

1, The time of heat treatment of power spring is 2~5 minutes.

2, The surface color of carbon metal will be silvery-white, light yellow, yellow, tawny, black, blue or gray after heat treatment. It is advisable when its appearance is from light yellow to blue, and pay attention to prevent it from rusting.

3, Stainless steel is advisable with spring color to light yellow.

4, SWIC nickle-plated is advisable when its appearance is not discoloration.

|

| Back |

|

|