When we talk about the material of the stainless steel spiral spring, our first thought is SUS material. But there are many kinds of SUS material in practical applications.

Dongguan Yongsheng Metal Products Co., Ltd specializes in R&D and production of spiral spring, power spring over the years, select high quality imported stainless steel material, 15% better than others on quality.

Today we explain and analyze the difference between SUS301 and SUS304.

SUS304(stainless steel): A kind of the most versatile stainless steel. As it contain Ni, so the corrosion resistance and heat resistance are better than Steek Cr, and it has low temperature strength , so the mechanical properties and work-hardening ability are very good, heat treatment without hardened, non magnetic, good strength, no more elastic, normally we often use the range of the width is 0.4T-1.0T.

So it’s used widely for bracket of the notebook which require strong construction, to meet the requirements of design, the grade must be assigned when you use it. Normally 3/4H is the best. If it needs to be tensile type, and if it’s be used for LCD bracket, 1/2H is the best. But if want to save money, they will use SUS430 instead of SUS304 in some companies.

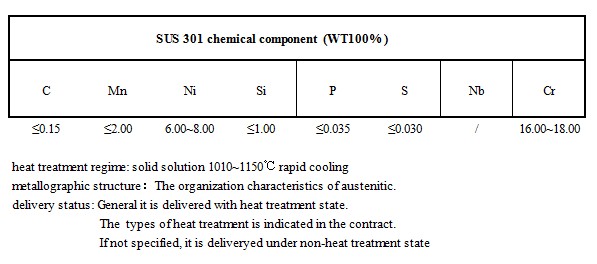

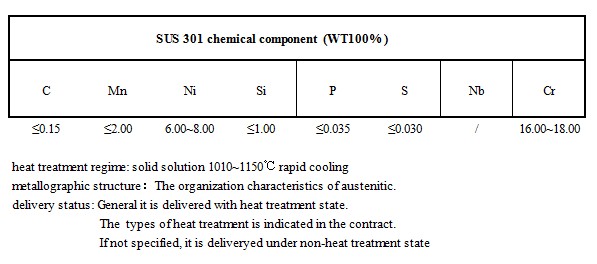

SUS301(stainless steel): the chromium content is lower than SUS304. The corrosion resistance is poor. But after low-temperature processing, the hardness will be higher, the application is wide.Because of its good flexibility, so it’s used widely for EMI of the notebook which is a part of elastic contact. But the common thickness is between 0.4T and 0.07T. The grade must be assigned when you use it, to meet the requirements of design(such as elastic force and strength). And it is important to note that SUS301 has metal crystalline direction. The higher grade, the firmer and crisper. It’s easy to cause corner and cracks on sidewalls if you’re not careful in molding.

The material and performance

SUS301: It’s suited to products which require flexible, high carbon content, high hardness, good fatigue resistance, worse ductility, difficult to stretch.

SUS304: It’s not suited to products which require flexible,low carbon content, low hardness.

So, although the corrosion resistance of SUS301 is lower than SUS304, the spiral spring is a kind of element for store elastic force, the fatigue resistance and ductility of SUS301 is better than SUSU304. If the hardness is similar, such as SUS 301 3/4H and SUS 304 H, although the hardness is same, but it will be uesd for a product which require elastic force, SUS304 is easy to produce elastic fatigue.

|